Another simple job but one that was ideal for digital printing. These sample caps were completed in a matter of minutes, and again show the versatility of being able to produce one-offs and sample work quickly, and at lower cost than setting up for screen printing for proofing purposes.

read more…Here at Tealwood in Waterlooville, Hampshire, we specialise in finding solutions to your unusual screen-printing requirements. We have a long history of engraving, pad & rotary printing, die-cutting, vacuum forming & laser engraving. See below a selection of our bespoke solutions to our clients previous printing needs. Contact Us

The challenge with this font for Pepsi was that the print area was curved but had too large a radius for Rotary printing. Pad printing wasn’t an option, so it had to be Screen printed. Because of the curve a screen and squeegee had to be modified to enable an accurate print of the Pepsi logo with no distortion and keep the three colours in register. We produce and print […]

read more…These trays were printed for well known restaurant brands, the requirement was simply to reverse print onto a durable material as a self adhesive tray insert. What we added to the job was to reverse print onto a clear textured material with a non-slip quality. This added dimension gave the finished result a useful edge in the catering industry. The inserts were then cut to size on the laser and […]

read more…4 colour Pad Printing is an art at the best of times, making sure the image is sharp and maintaining registration of all the colours. The fine detail in this job meant a challenge, but the finished result shows how well it can be achieved.

read more…

The production of pump badges and other drinks industry items shows the versatility of what we do in terms of the various processes involved in completing a product. Some of these can be multi-layered lenses creating a 3D effect, some on flat sheet, we take on a huge variety of these challenging jobs. These particular badges were screen printed multi-up in 4 colours, they were then vacuum formed (in-house), to […]

read more…

Here is a typical example of much of the rotary printed work we do. Although pretty simple, being only one colour, the important thing is to make sure the start and finish position of the numbers are correct. Working through large numbers of this kind of item quickly is not a problem. We can also print as many different colours as you like, and work with much larger items.

read more…

Absolute precision was the key with this one! A jig was engineered to enable printing every line in exactly the right position, quite important on an aircraft instrument! Each line was printed individually as the object was rotated, to keep it perpendicular with the printing pad. The end result was very satisfying, these are the kind of challenging jobs we can take on.

read more…

These large cylindrical font housings are typical rotary printed items. They look simple enough to print as you watch the video clip, but accurate setting up of the job was important to ensure the finished print was lined up correctly with the threaded boss at the rear of the cylinder and in the centre. Although only a 3 colour job, they had to be printed in 4 operations to effectively […]

read more…

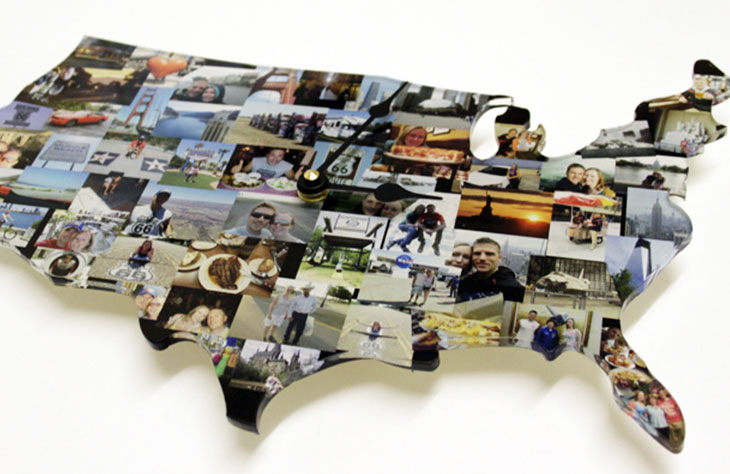

This clock, was reverse printed with photographic images onto 5mm clear acrylic and cut to the shape of America on our laser. Any number of designs, shapes and sizes can be done, the choice is yours!

read more…These speakers were a promotional ‘give away’ and are typical of simpler, high volume work. These were printed on the one-colour machine but we could just as easily print multi-spot colours or in 4 colour process for tint work etc.

read more…